RIP

Repair in Place Rate (RIP) (その場での修復率)

RIP is an optional input variable (Parts and Structures/MTBF Data). It represents the proportion of failures of an item that do not require its removal to restore its parent to operation. Its effect (when greater than 0) is to reduce the demand rate associated with the item’s MTBF. If RIP is left blank, the value will be set to 0.

RIP is the number of failures of this item that do not require its removal to restore its parent part to operation, expresses as a decimal. TEMPO uses this value to reduce the demand rate associated with this part’s mean time between failures (MTBF). The allowable range is 0 to 1.

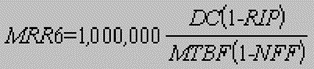

The value is used to modify the value of MRR6 obtained from the following calculation:

Duty cycle is an optional input. If it is left blank, the default value will be set to 1. Its value will have no effect if the data set contains a value in the MRR6 field

Note: RIP is only used when no MRR6 value is present. It is used to adjust an MTBF value to make an estimate of MRR6. Using it does not cause the SRUs comprising the LRU to behave as LRUs. Separate discussion of Items that are always Repaired without Being Removed (Repaired in place, RIP = 1) and Items that are Sometimes Repaired without Being Removed (Repaired in Place, RIP < 1) indicates how to model situations in which an LRU’s children become LRUs themselves when the LRU is not removed.

« Back to Glossary Index